With careful design of the dirty water pit so that our pump is taking the mud AND the dirty water, we are sure to get as much out as we can.

This keeps the water as clean as possible as it is pulled into our system.

If your pit isn’t full of mud, it is less dirty and needs hardly – if any – cleaning

Over 30 years we have developed a specific range of safe chemicals that are totally effective. We continually test and change where necessary.

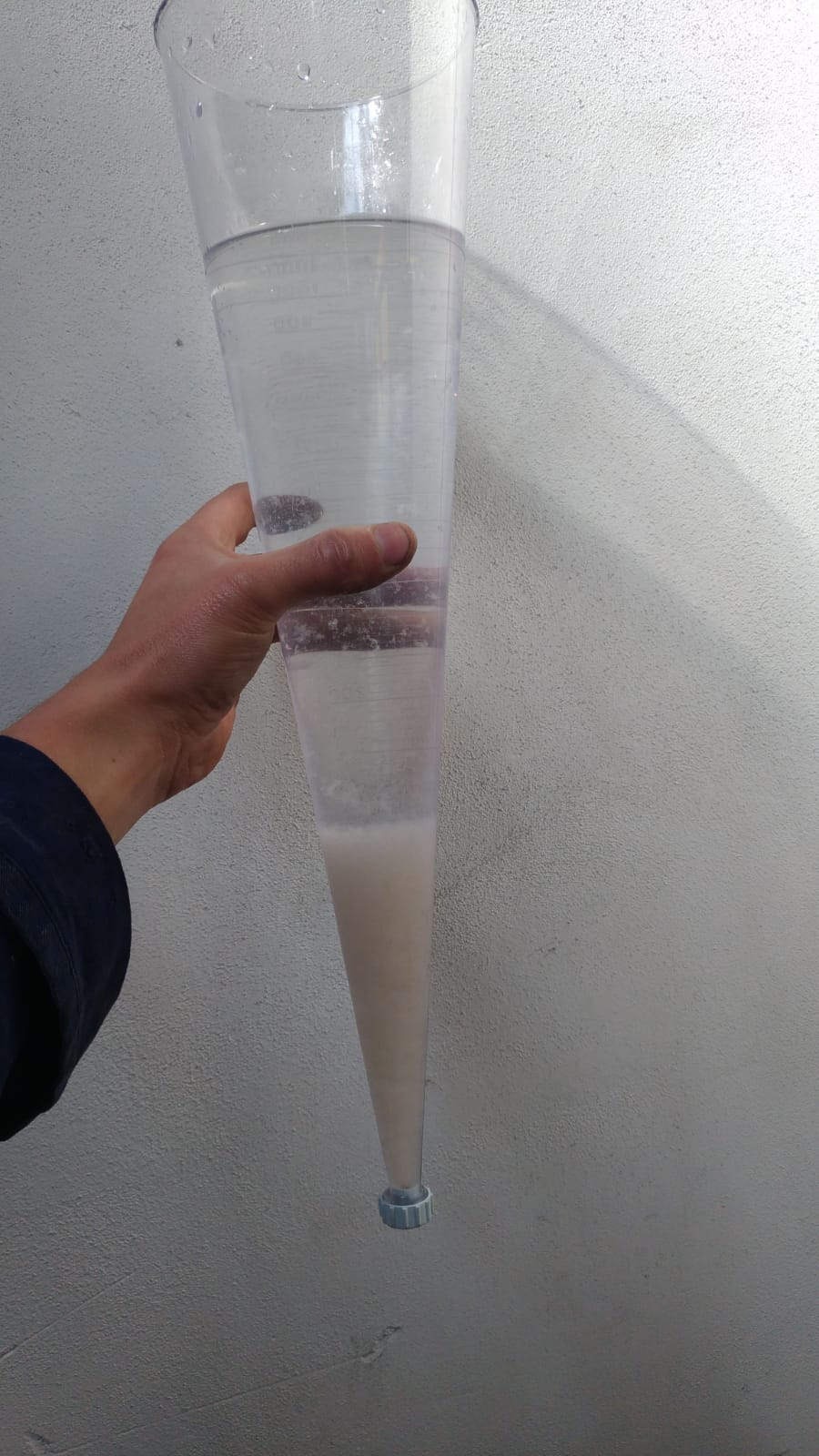

A flocculant is added to take care of natural stone particles. This world together with a coagulant which binds together the lighter particles, making them heavy enough for the flocculant to work.

Dosing can be adjusted by the customer to suit changes in material load.

Chemical attractionStanding water means settlement.

Because our system is on demand, we are moving the water all of the time so the water is constantly being cleaned

We are somewhere around 20 microns for ALL of the water, this is pumped under pressure to your machines and can be further filtered as a local level for CNC spindles to 1 Micron

FURTHER FILTRATIONThe entire system is controlled automatically from one panel – either switches or touch screen – where the only real intervention is to turn on in the morning and off at night.

Each segment can be manually or automatically controlled.

The way to should be, not multiple panels and switches …..

just like turning on the lights !

TOTAL CONTROL